LV CONTROL & POWER CABLES

(Reference Standard- IEC 60502-1, BS-5467, BS-6724, IS-1554 P-1, IS-7098-1)

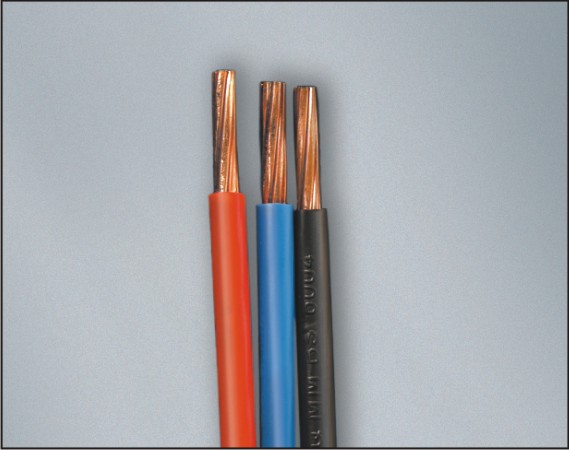

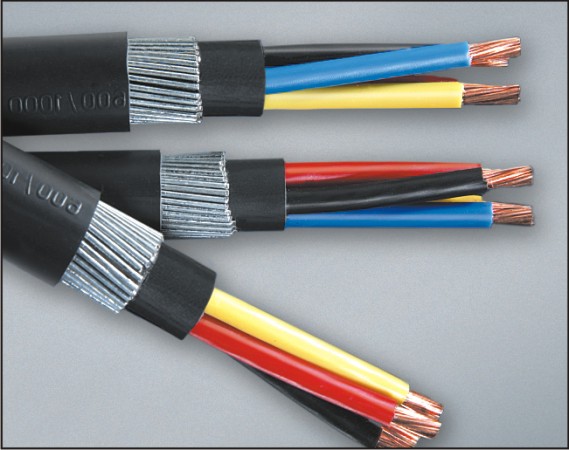

Control & Power Cables are used for Indoor, Outdoor application or for control panels, power & switching systems, industrial plants and by electricity boards.

Operating temperature: 70°C, 85°C, & 90°C (depends upon selection of insulation compound).

Product Size: Single or Multicore 0.50 Sq.mm to 4 Sq.mm for Control Cables and 1.5 Sqmm to 50 Sqmm for Power Cables.

Voltage grade: 600/ 1000 V/ 1100V.

Conductor : Annealed bare Copper/ tinned Copper, solid or stranded Copper conductor (IEC -60228, IS-8130 Class 1 & 2).

Insulation: PVC / XLPE.

Armouring: Galvanized round and Flat strip conforming to IS/BS Standard.

Sheathing: PVC/ FR/ FRLS/ FROR/ FRRT/ LSF Inner & Outer sheath.

Note: Copper tape screening as per customer requirement.

-

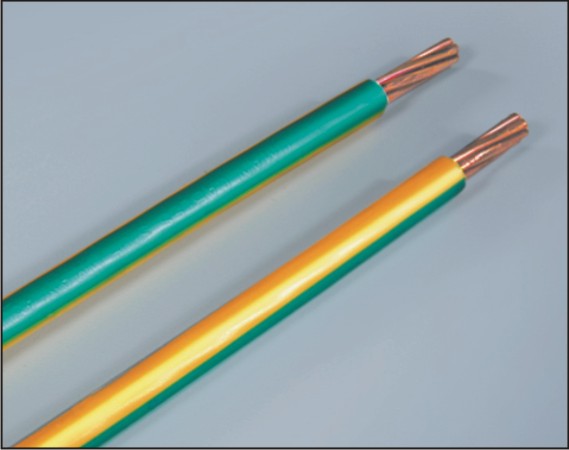

Earthing Cable

-

Earthing Cable

-

Unscreened

| Insulation Material | Tensile strength | Elongation at break | Operating Temp. | Short Circuit Temp. Rating | Dielectric Constant | Dissipation Factor | Volume Resistivity |

| N/MM² | % | C° | C° | 10³Hz | 10³Hz | Ω - Cm | |

| PVC | >13 | 250 | 70 | 135 | 4~7 | 0.02~0.04 | 10 |

| Polyethylene | >14 | 500 | 70 | 200 | 2.27 | 0.0003 | 10 |

| XLPE | >15 | 500 | 90 | 250 | 2.3 | 0.005 | 10 |

| Insulation Material | Abrasion Resistance | Oil Resistance | Solvent Resistance | Water Resistance | Flame Retardance | Radiation Resistance | Flexibility | ||

| PVC | |||||||||

| Polyethylene | |||||||||

| XLPE | |||||||||

|

POOR

|

FAIR

|

GOOD

|

Copyright © all rights reserved Associated Cables Pvt. Ltd. | 2007-08